Gases we use

The PBF process commonly use nitrogen withmaterials like stainless steel, or Argon for othertypes of materials. We can help you analyse whatis the best performing mixture for your DED orPBF process. Another gas solution is helium, which is used in the EBM process, although beingexpensive for this process, it consumes a littleamount.

On the other hand, the FDM process uses argonnitrogen and small percentages of hydrogen inargon, but only in the metal sintering phase. Forfurther information don’t hesitate to contact us.

On the other hand, the FDM process uses argonnitrogen and small percentages of hydrogen inargon, but only in the metal sintering phase. Forfurther information don’t hesitate to contact us.

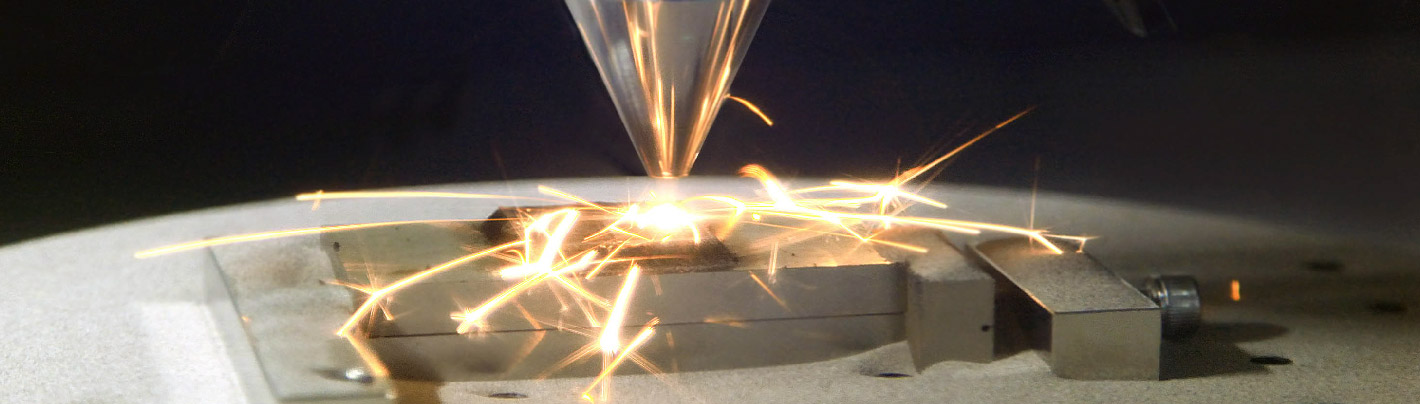

Argon for additive manufacturing

Thanks to its chemical-physical characteristics, Argon is a frequently used gas in the additive manufacturing processes. It's mostly used for those materials that are particularly reactive with oxygen or other air components.

Nitrogen for additive manufacturing

Under normal conditions, Nitrogen is an inert gas but at high temperatures it can react with some materials which are also used in 3D printing.

Helium for additive manufacturing

Helium is an inert and very light gas. Its chemical and physical properties make it ideal for both PBF and DED 3D printing processes. Since Helium is very rare and expensive, it is mainly used in EBM processes, which are known for their low gas consumption. In the DED process Helium is often used, but mixed with other gases.

3D Pro® sinter3 for additive manufacturing

This mixture is especially designed for the sintering process after the FDM process.

Do you still have questions?

At Nippon Gases we are called “The Gas Professionals” for a reason, and it’s because we’ll be able to solve any doubt.